| Many types of smoke and dust can cause health hazards once inhaled into the human body. People will become extremely and permanently sensitive to smoke as a result, which will mean that this hazard will continue to exist, even for small amounts of smoke, and may cause asthma and other respiratory diseases. A high-performance smoke and dust purification system will help with |  |

►Replacement cycle: Under normal conditions

@When there is a lot of dust: It is recommended to replace it after about 1 to 2 months. Blockage of the filter will affect the performance of the soot filter suction. |

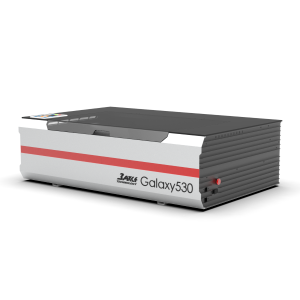

FEATURES

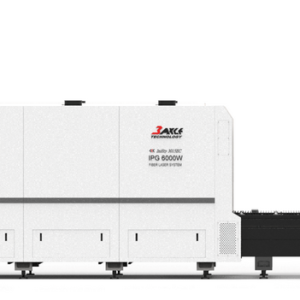

►Specially designed for laser marking and engraving machines, it can eliminate the iron powder/smoke/odor emitted during the marking process in the shortest time. It is discharged into the smoke filter for filtration within a certain period of time.

►Suitable for filtering toxic smoke/odor emitted by manual soldering.

► Can be placed next to a UV direct spray machine or 3D printing machine to filter odors, effectively improving pungent indoor odors.

► The large suction performance is suitable for desktop laser cutting machines.

►Mobile integrated chassis design, small footprint, easy to use when plugged in.

►You can choose to switch to single-tube configuration or use dual-tubes at the same time according to on-site needs.

► For processing processes with strong odor, it is recommended to take over the external discharge, filter it and then discharge it outdoors. Effectively keep the room free from odor pollution.

The rigid bamboo tube can be bent at will, and the adsorption direction points |

Soft suction cover, can withstand high temperatures up to 100~150 degrees |

The suction hood is equipped with an adjustable opening and closing air valve |

Equipped with flange seat, external exhaust duct can be installed |

perfect match Perfectly matched with laser engraving machine, high wind speed performance reduces working environment pollution |

Designed and manufactured in Taiwan Designed from the inside out, combined with years of export demand standards, we have specially developed a model suitable for Taiwanese processing users. Made in Taiwan has high quality control and safety requirements, so that you can feel the value and trust of Made in Taiwan. |

|

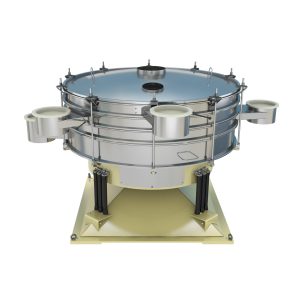

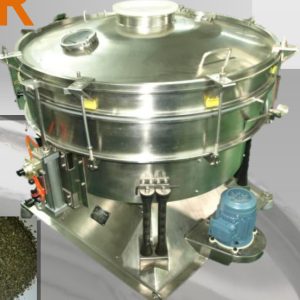

One-to-two suction is equally strongSave purchase costs. Reduce supplies inventory. More space usage The dust evaporated during the laser processing process will contaminate the lens, causing damage to the lens and deterioration of engraving quality. The strong suction power ensures that dust in the processing area can be quickly sucked away, and the volatile smoke odor can be significantly reduced. There are many types of consumables to choose from. Our company provides consumable selection suggestions based on the pollution emitted by processing. Reduce consumable expenses. |

|

Suitable for use with laser cutting machinesNumerous filters on the market are only suitable for pollution filtration in micro-processing tasks. They have poor wind speed effects and are easy to choose because they are low-priced. MK-1hpmini mainly focuses on high wind speed and can be used in laser cutting machines. Especially for filtering consumables, it also carefully budgets for customers and provides the lowest consumable cost as much as possible, but can achieve the best filtering effect. We can provide corresponding suggestions for different filtering needs. This model is suitable for use with models on the market that have a working range of less than 900mm x 600mm for one-to-one use (including 600mm x 400mm). |

Equipment Specifications

|

|

中文 (台灣)

中文 (台灣) Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.