|

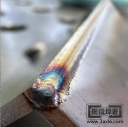

Handheld laser welding machine can be widely used in hardware welding, stainless steel furniture, cabinet tableware, oven, elevator, shelf stainless steel door and window railing, electric box and other industries. Laser welding is mainly aimed at welding and cutting of metal objects, which makes up for the trouble of large heat fusion, easy deformation and post-processing of thin plate welding by traditional argon arc welding technology. The hand-held fiber laser cutting function performs partial processing on the formed object, or quickly cuts and modifies the object without using a professional cutting machine Three laser welding modes can be adjusted according to different welding needs. By replacing the laser sleeve, it can be quickly used for cutting, and it is a multi-purpose machine. Integrated design of the whole machine, built-in water cooler, 220V voltage access, more convenient to move and connect to electricity. No welding experience can quickly learn to operate, saving you expensive technical labor costs! At present, the salary of technical personnel has increased exponentially; and the operation of laser welding is simple and convenient, and the skilled hands can operate on the machine, solving the problem of difficult to find technical personnel. |

|

Fiber laser is a newly developed fiber laser in the world, which outputs a high-energy-density laser beam and gathers it on the surface of the workpiece, so that the area irradiated by the light spot on the workpiece is instantly melted and vaporized. Compared with the bulky gas laser and solid-state laser, laser welding can be realized by using the irradiation position. It has gradually developed into the preferred laser source in the field of high-precision laser processing. |

Specifications

| Brand | 3AXLE | ||

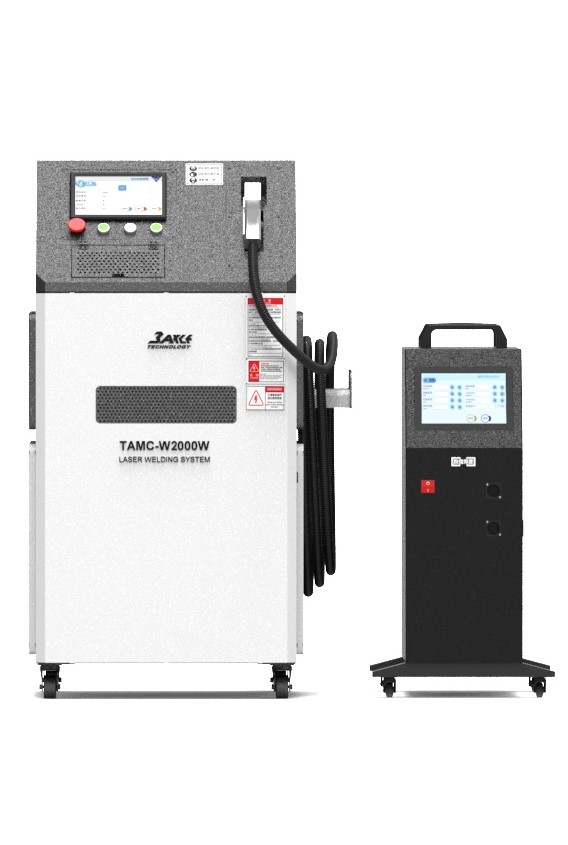

| Model | TAMC | TAXC | TAMC |

| Cabinet style |  |

|

|

| high cabinet | low cabinet | 3000W High power cabinet | |

| Laser power | 1000W / 1500W / 2000W | 1000W / 1500W / 2000W | 3000W |

| Fiber length | 8m | 8m | 8m |

| Laser wavelength | 1070nm | 1070nm | 1070nm |

| Laser welding width | 1~5mm | 1~5mm | 1~5mm |

| Auxiliary positioning method | red light | red light | red light |

| Laser mode | ―Type (standard) (gun body weight 0.8kg) | ―Type (standard) (gun body weight 0.8kg) | ―Type (standard) (gun body weight 0.8kg) |

| Type, ― Type, ○ Type, ◎ Type, △ Type, ∞ Type (gun body weight 1.2kg) (optional) | Type, ― Type, ○ Type, ◎ Type, △ Type, ∞ Type (gun body weight 1.2kg) (optional) | Type, ― Type, ○ Type, ◎ Type, △ Type, ∞ Type (gun body weight 1.2kg) (optional) | |

| Cooling System | High wattage dedicated built-in water chiller | High wattage dedicated built-in water chiller | High wattage dedicated built-in water chiller |

| ambient temperature | 15-35 ℃ | 15-35 ℃ | 15-35 ℃ |

| environment humidity | < 70no condensation | < 70no condensation | < 70no condensation |

| Operating Voltage | 220V 60HZ 20A (380V above 2000W) 1000W – single phase AC220V 50~60Hz (power consumption 4kw) 1500W – single phase AC220V 50~60Hz (power consumption 5kw) 2000W – Three-phase AC380V 50~60Hz (power consumption 7kw) (2000W needs to be matched with 20K isolation transformer) |

220V 60HZ 20A (380V above 2000W) 1000W – single phase AC220V 50~60Hz (power consumption 4kw) 1500W – single phase AC220V 50~60Hz (power consumption 5kw) 2000W – Three-phase AC380V 50~60Hz (power consumption 7kw) (2000W needs to be matched with 20K isolation transformer) |

3000W – Three-phase 380V ±10%, 60Hz (power consumption 15kw) |

| Weld thickness | 0.5-5mm | 0.5-5mm | 3-8mm |

| Weld requirements | < 0.5mm | < 0.5mm | < 1.5mm |

| Equipment size | 650mm x 620mm x 120mm | 950*600*1100mm | 1240*1030*660mm |

| equipment weight | 150kg | 150kg | 200kg |

Feature

Design from 3AXLE team A brand new model designed and built by a team of 3AXLE from the inside out, the industry’s thickest sheet metal material is used, and the overall rigidity is full. |

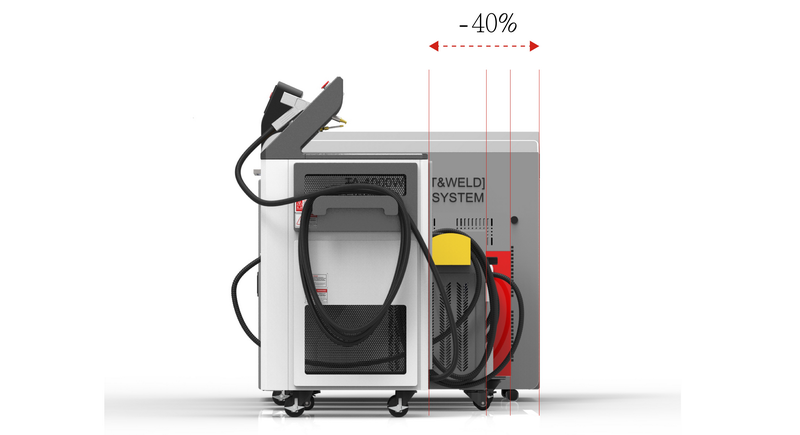

Create the smallest volume in the industry The TAMC model is the model with the smallest floor area in the industry, reducing the floor space by about 40%, and the overall height does not exceed 120cm, which is more suitable for truck transportation. Reduce plant footprint. |

|

Different hand-held welding heads can be selected for various needs such as external welding, internal welding, right angle welding, narrow edge welding, and large spot welding of metal parts. |

Large screen touch panel User-friendly interface, you can touch to adjust the power/frequency to switch quickly. No complicated operation steps, you can get started in a short time. |

High-quality aluminum alloy handle It conforms to the ergonomics of the hand during vertical work, and only weighs 0.8KG, which reduces occupational injuries caused by long-term work. |

Unique gun body storage design It is more suitable for the operator to operate the height, reducing the physical burden caused by repeated bending, and a more intuitive storage method. Helps maintain good storage habits |

Operations console security configuration The console is equipped with a safety emergency stop switch. Pressing the emergency stop switch in any emergency situation can power off the whole machine. And equipped with key control lock to avoid equipment damage or dangerous accidents caused by unauthorized operation by unfamiliar personnel |

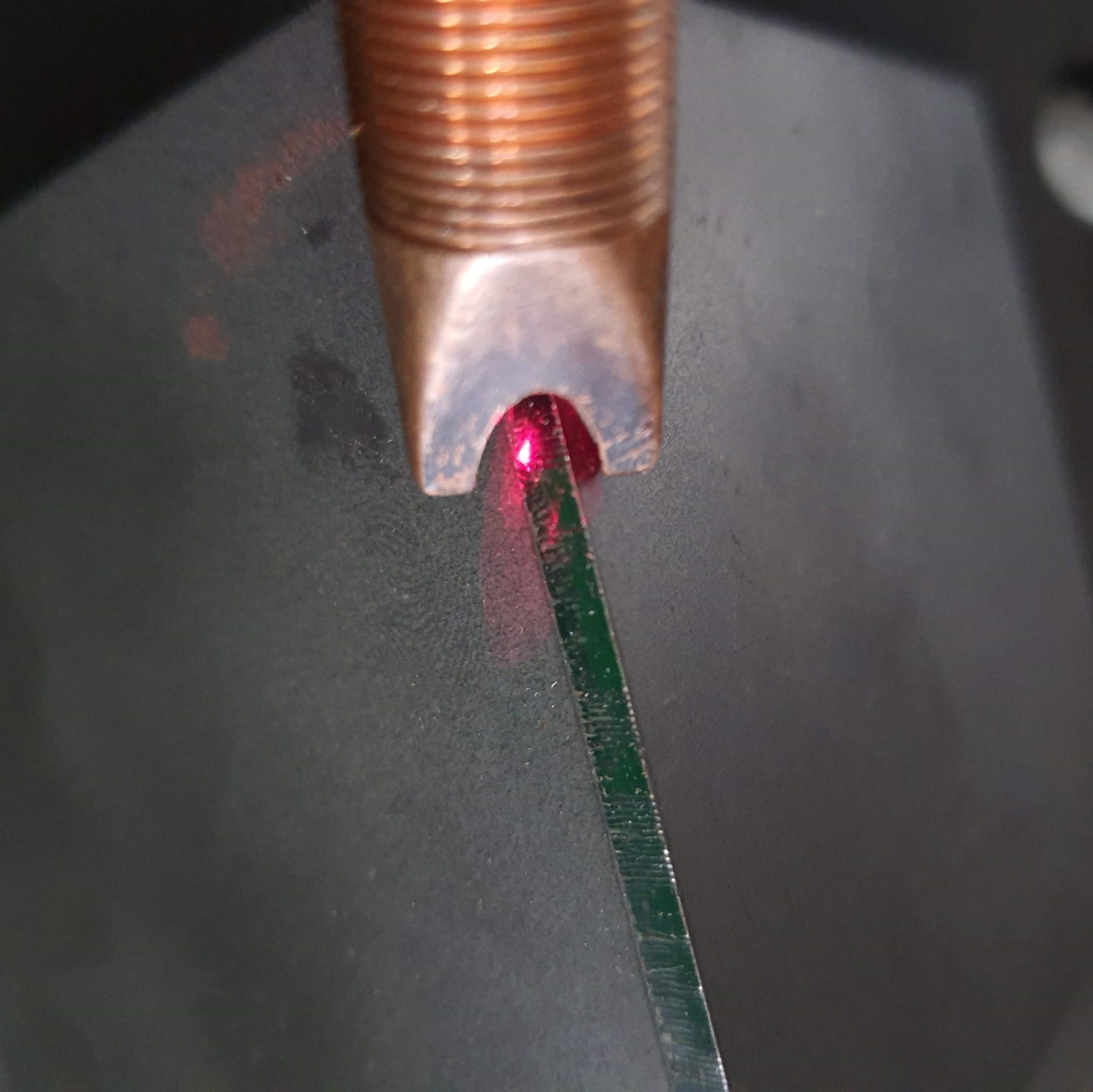

Internal projection red light positioning Users can understand the joints of laser welding more clearly, and the welding quality and efficiency are more accurate |

Fiber Optic Cable Storage Optical fiber cables are very fragile, although our company has multiple layers of protection on the outer layer of the cable. However, in the construction environment, in order to avoid the cable being broken by heavy objects, a space for accommodating cables is specially configured. Cables that are too long can wrap around the top of the device. |

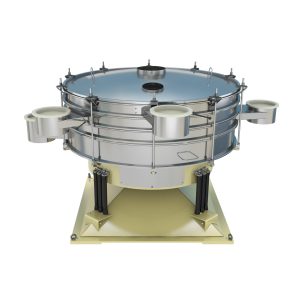

Automatic feeder With the automatic feeder, filler welding can be carried out, and the welding seam is larger or the strength needs to be strengthened. |

Filler Welding Mode For larger gaps and strength requirements, the advantages of wire filler welding are closer to traditional welding methods, and low-tech operators can quickly get started |

Schematic diagram of the complete construction of the equipment |

A variety of models are available for selection, please refer to the equipment specifications |

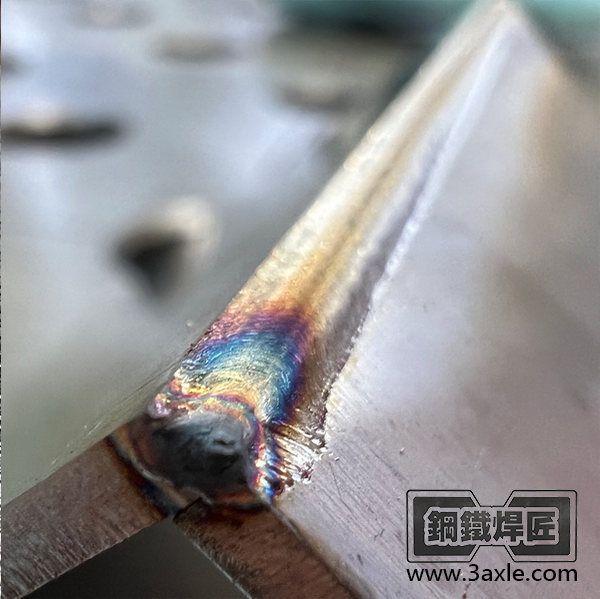

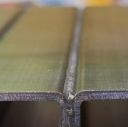

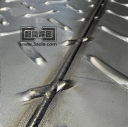

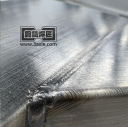

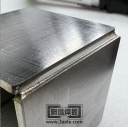

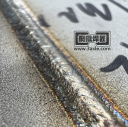

Introduction of actual machine operation

|

|

|

|

|

|

|

|

|

|

Others

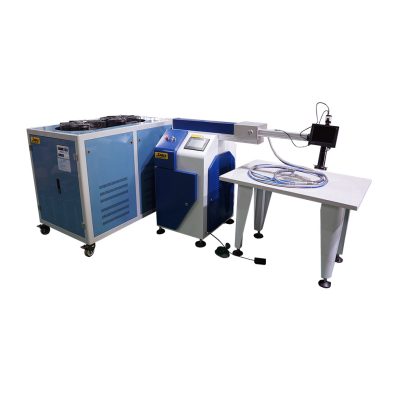

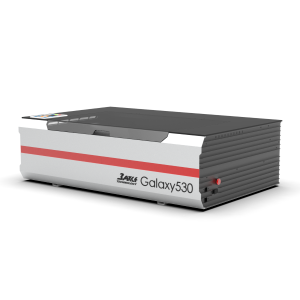

| Double optical path precision laser welding machine

“Fixed/Handheld” |

|

| TAF-200W laser welding machine |  |

| TAFD series jewelry welding machine |  |

| TA-WF1000D

Multi-axis automatic fiber laser welding machine |

|

中文 (台灣)

中文 (台灣) Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.