| • Laser wattage supports 150W-320W (optional) • High-power constant-power CO2 laser, high light output efficiency, thin light spot, stable light output for a long time without attenuation. • Comprehensive dust-proof design solves the problem of dust contamination of lenses. • Unique follow-up system design ensures small gaps and high smoothness on the cutting surface. • Can punch holes, draw lines and cut continuously.. • Application range: • Applicable materials: |

|

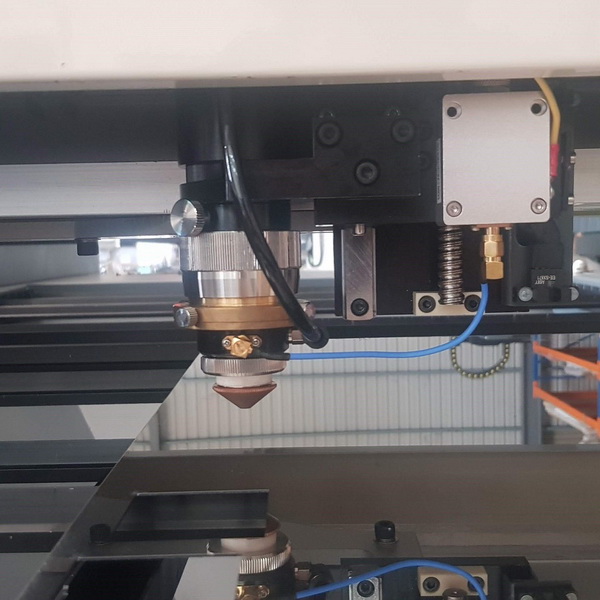

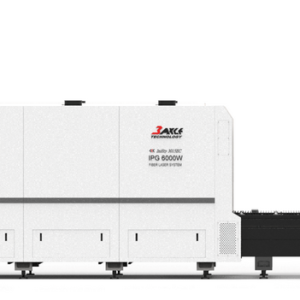

• High precision: XYZ adopts high-precision imported ball screw transmission, which greatly improves the speed and cutting accuracy of the equipment and extends the life of the machine. • Servo motor and drive: Using Japanese Mitsubishi servo motor and supporting drive, it has long life, high precision and strong stability. • Optical fiber-grade metal-specific follow-up focus adjustment system: Sensing the uneven surface of the metal plate, it automatically adjusts the focus to ensure the best cutting results. • The exclusive design can fine-tune the laser cutting head to ensure the best cutting effect. The laser head has a built-in automatic anti-collision device to effectively protect the laser head and reduce the risk of human-caused failure. • American metal optical lenses, durable and more effective in reflecting light paths. • Industrial refrigeration water coolers. • Powerful smoke exhaust device to effectively eliminate smoke. • Dedicated color touch control panel for mixed cutting, spare USB and network cable sockets, and supports multiple file formats such as DXF, PLT, and AI. |

Features

| Material | 150 watts | 320 watts |

| Stainless steel | ≦1.2mm | ≦2.0mm |

| Carbon steel | ≦1.5mm | ≦3.0mm |

| Galvanized sheet | ≦1.0mm | ≦2.0mm |

| Acrylic | ≦30mm | ≦40mm |

| Dense board | ≦8mm | ≦12mm |

| Plywood/multilayer board | ≦15mm | ≦20mm |

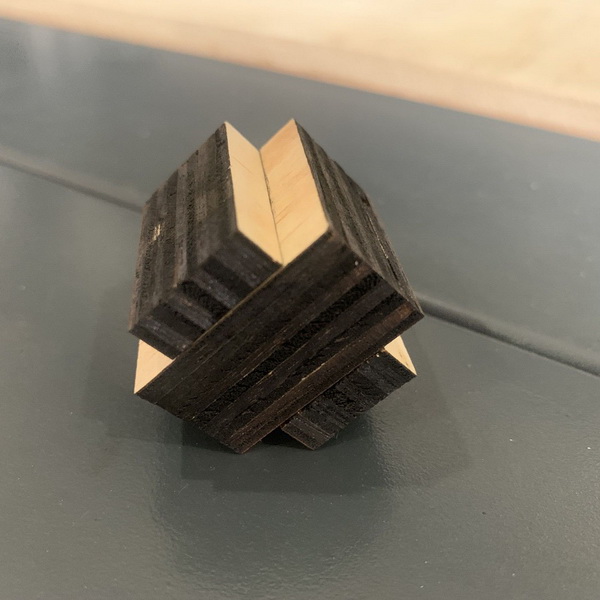

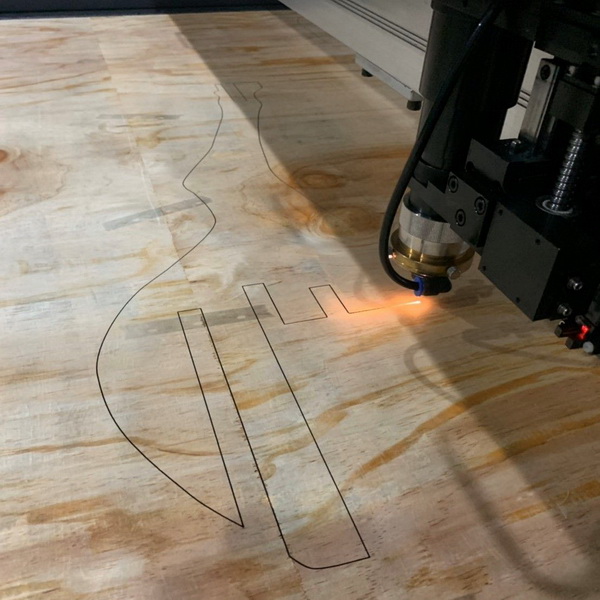

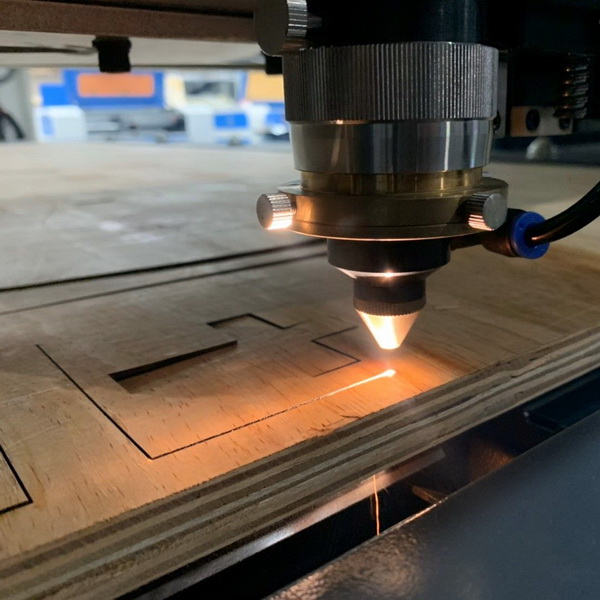

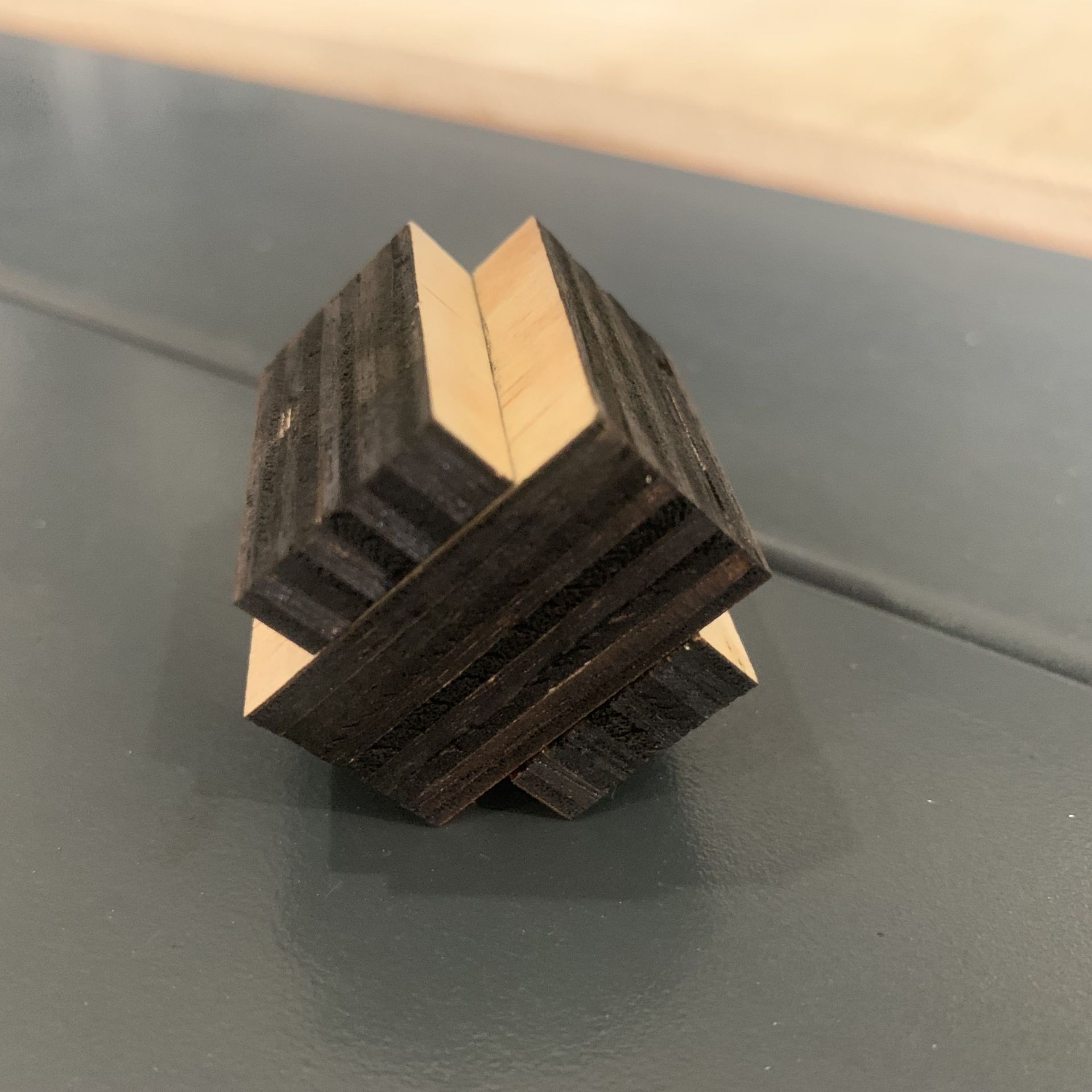

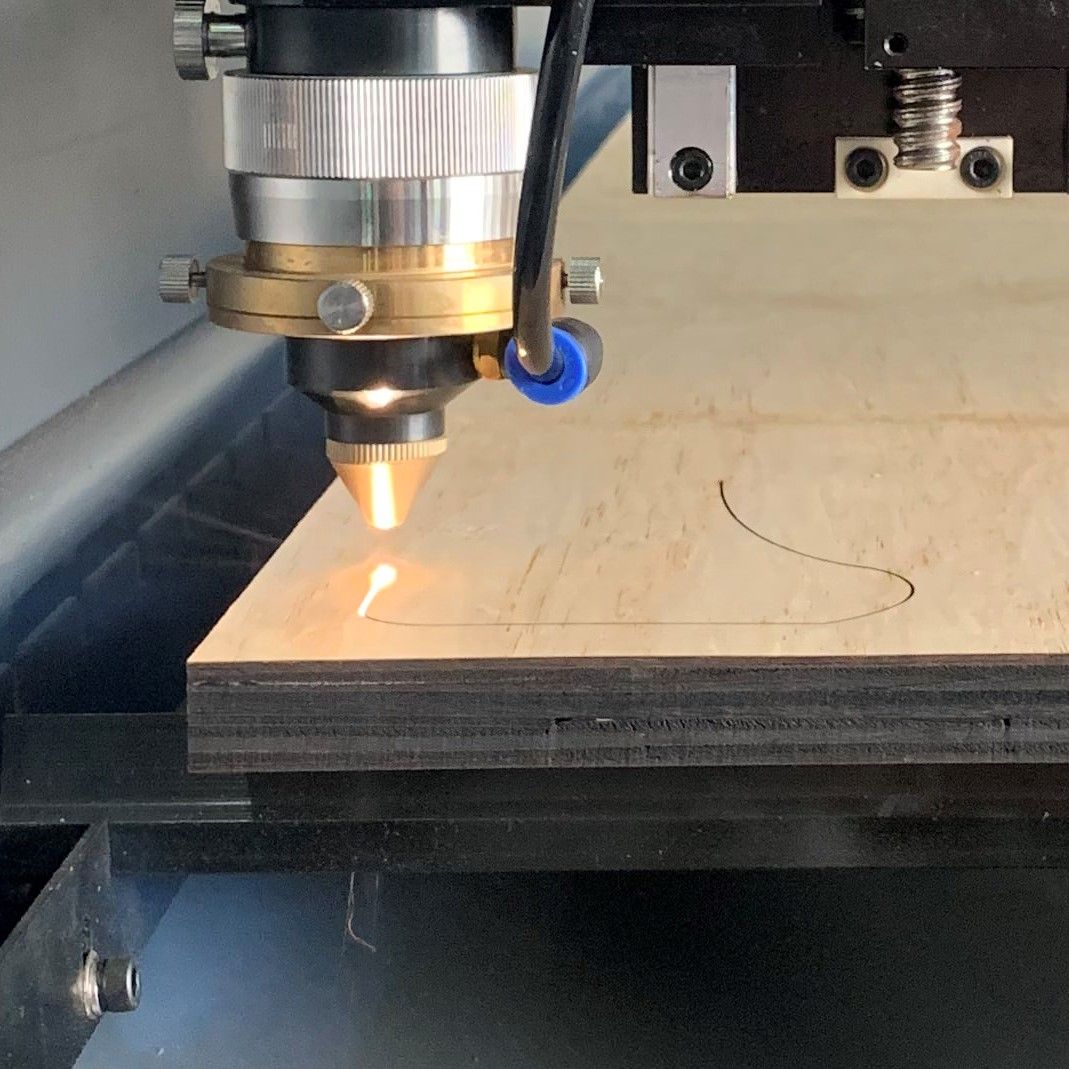

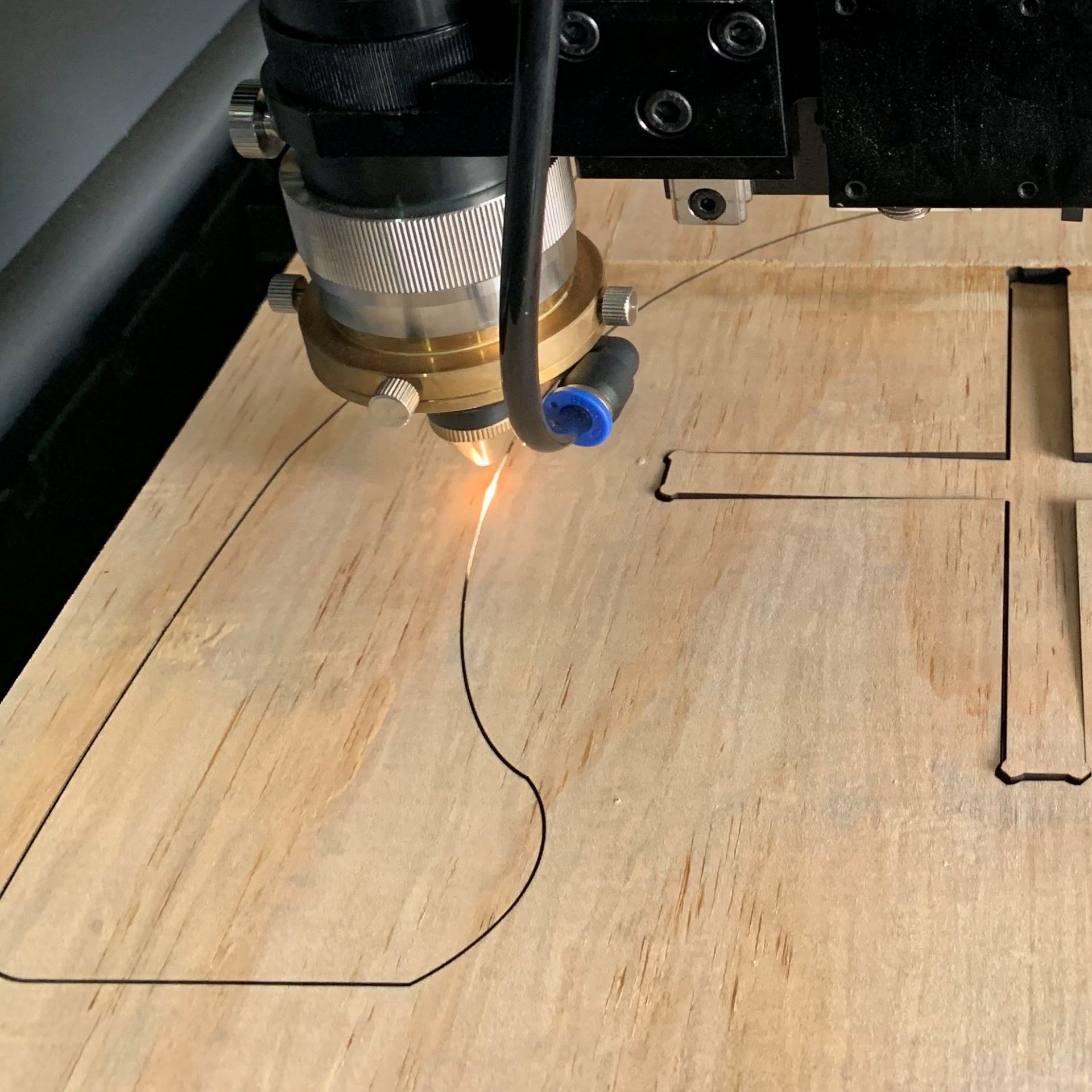

18mm plywood cutting performance, high wattage cutting reduces edge carbonization and blackening |

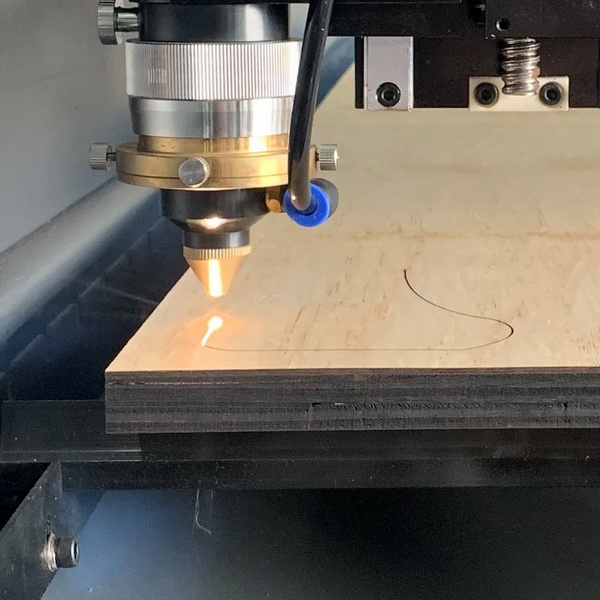

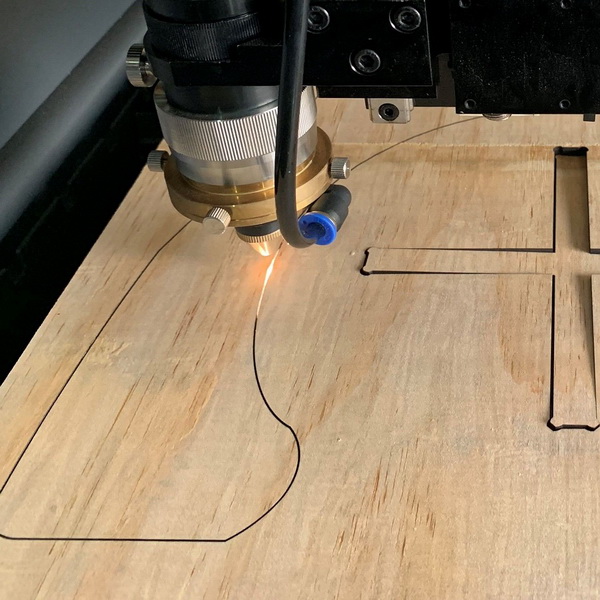

Laser non-contact cutting, fast loading and unloading positioning |

The three axes of XYZ all use Japanese Mitsubishi servo motors |

The software is optimized and can be inserted into vector line drawings |

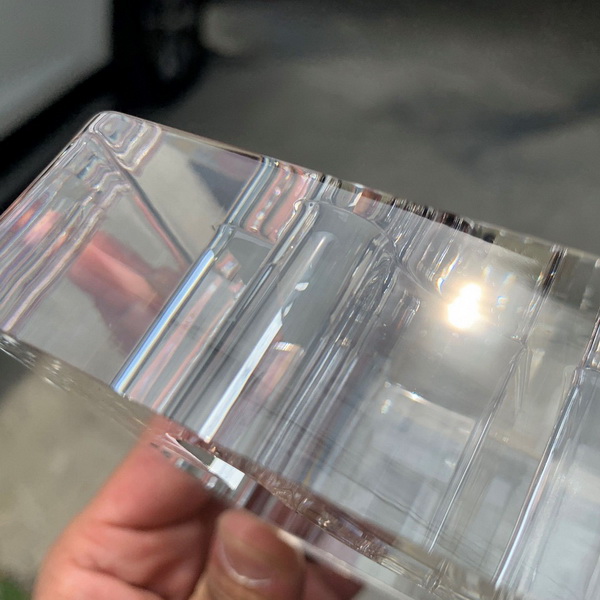

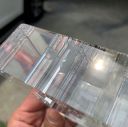

Clean, bright and translucent cutting effect without ripples |

No technical threshold. No need for post-processing, |

|

Ultra-high cutting performance

• High wattage penetration capability, excellent fine seam cutting performance for wood board cutting. • Laser is a non-contact processing, and the correct focal length and laser energy can achieve good cutting quality.

|

|

Choose the right processing method

• For cutting smaller objects or the need for vertical angles, laser cutting can be easily achieved. |

|

Industrial-grade transmission mode • The transmission mode of this machine is ball screw, with ultra-high-precision display, especially for long-distance cutting requirements for positioning and alignment, and the accuracy can reach extremely high standards. • Equipped with the same dust cover used in industrial machinery to avoid external dust factors causing instability in equipment operation. |

|

Humanized control system

• The difficulty of equipment operation directly affects the operator’s willingness to learn. This machine is equipped with the laser processing control system with the highest market share currently.

• With 10 years of sales education and training, our company has a sound teaching method for first-time users. |

|

Replaceable sword support bars

This machine is equipped with two lengths of blades, and the user can adjust the position of the blades according to the processing application time.

|

|

Metal & non-metal dual-purpose cutting

This configuration is optional. Users can select this function for sheet metal cutting purposes. #Please refer to the cutting parameter table above for the cutting performance of various types of plates. |

|

Laser output stability

• Wide-range cutting stability is believed to be one of the concerns of the industry. How to maintain stable output of laser energy within the entire working range to achieve consistent cutting and penetration performance. I believe this is a quality that many affordable machines cannot maintain. |

|

Smoke and odor filtration system

• This equipment is often one of the most overlooked items. Our company has corresponding filter models for different material pollution. |

|

Comes with one year warranty

• In addition to warranty, we also enjoy after-sales service and technical support. • Standard parts, easy to replace. So you don’t have to worry about the problems. such as lack of parts or discontinuation of replacement parts |

|

Maintenance plan

• Our company provides complete equipment maintenance projects to perform regular equipment maintenance, so that your equipment can be used for a longer period of time. • Compared with basic maintenance and major maintenance plans and repair fees, regular maintenance can reduce unnecessary maintenance expenses. • It can also regularly understand the current status of the equipment to take early precautions and reduce the occurrence of equipment shutdown when it is urgently needed. |

A processing method that truly saves consumablesThe advantage of laser cutting is that there is no need to reserve too much cutting spacing, and it is easier to control the layout quantity and plate consumption. In addition, the time spent on loading and unloading materials of the laser cutting machine is relatively reduced, and there is no problem of clamping and adsorption stability. Whether the board is acrylic/wooden board, etc… Just place the cutting platform and confirm the height focus of the laser head to start cutting. In addition, the remaining materials can also be cut and saved for other design purposes. Really achieve full plate cutting efficiency. #This system also supports the automatic layout function. Import the required cutting graphics into the software to automatically layout the objects. Significantly reduce the time and energy spent by art editors on typesetting. |

|

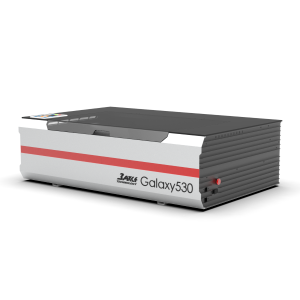

Equipment Specifications

| Device model | TADH-1313 | TADH-1325 | TADH-1530 | TADH-2030 |

| Laser power | Glass tube 150W / 320W, Metal tube 80W / 100W / 120W / 150W | |||

| Cutting range | 1300*1300mm | 1300*2500mm | 1500*3000mm | 2000*3000mm |

| Positioning accuracy | ±0.05mm | |||

| Cutting speed | 0-300mm/s | |||

| Cutting thickness | 320W: Acrylic ≦ 30mm / Dense board ≦ 25mm / Plywood ≦ 18mm | |||

| Drive mode | Japan Mitsubishi servo motor + ball screw + linear guide | |||

| CCD patrol | Optional add-on purchase | |||

| Connection method | USB transmission cable / flash drive / network port RJ45 / Wifi (optional) | |||

| Electricity demand | Three-phase 220V 60Hz 50A | |||

| Constant light path system | X-axis constant light path | |||

| Cooling method | CW 5000/ CW 6000 ice water machine | |||

| Equipment size | 2450*1994*1250mm | 3650*1991*1250mm | 4400*2100*1200mm | 4500*2200*2520mm |

※Specifications are subject to revision without prior notice. Please refer to the specifications on the latest quotation.

Reference Sample

|

|

|

|

|

|

|

|

|

中文 (台灣)

中文 (台灣) Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.