[RAGOS] AG series automatic polygonal metal bending processing center

Mass production of artifacts

The maximum thickness of the plate is :2mm aluminum sheet/1.5mm carbon steel sheet/1.2mm stainless steel sheet

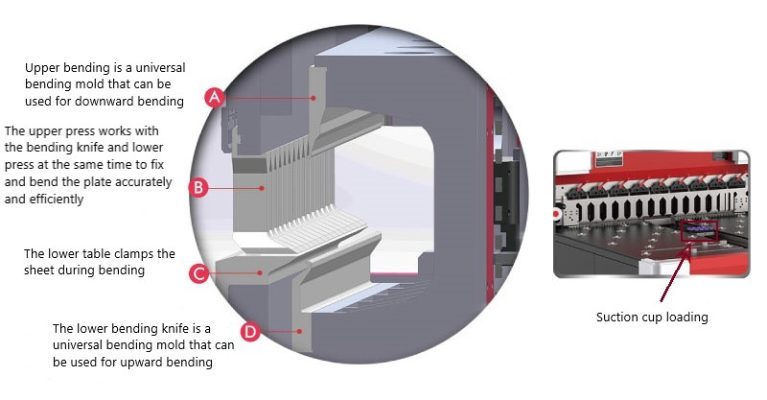

※AG-1000 / AG-1500 has a “suction cup loading” structure.

If you have “pressure loading” requirements, please refer to AGP-2000 / AGP-2500.

|

|

Four specifications available

AG-1000Bending length: 1000mm Sheet length: 1600mm Sheet material width: 1000mm ※Suction cup loading |

AG-1500Bending length: 1500mm Sheet length: 1100mm Sheet material width: 1250mm ※Suction cup loading |

AG-1500Bending length: 2000mm Sheet length: 2100mm Sheet material width: 1250mm ※ Press down and load |

AGP-2500Bending length: 2500mm Sheet material length: 2600mm Sheet material width: 1250mm ※ Press down and load |

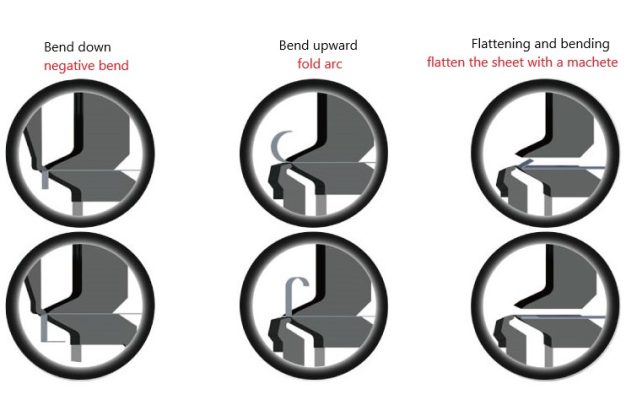

BENDING FORMAT

UNIVERSAL BENDING TOOLING

It can automatically adapt to various geometric shapes to achieve mass production

The interface display shows

a 17-inch dust-proof LCD screen with precise touch control, providing customers with an intuitive interactive programming experience.

Adopting STAR300-LGX CNC system and operating system WIN7+OS, it is simple to operate and easy to use, and can cover the entire production process.

※The equipment is updated from time to time. The pictures, functions, and specifications on this page are subject to change without prior notice. Please refer to the specifications on the latest quotation.

※Some functional accessories are optional.

Equipment Specifications

| Device model | AG-1000 | AG-1500/AGP-1500 | AGP-2000 | AGP-2500 |

| Bending length | 1000mm | 1500mm | 2000mm | 2500mm |

| Sheet length | 1100mm | 1600mm | 2100mm | 2600mm |

| Sheet material width | 1000mm | 1250mm | 1250mm | 1250mm |

| Bending height | ≦ 170mm (optional height ≦ 320mm) | |||

| Minimum molding size of four sides | AG series: ≧350*150mm

AGP series: ≧360*180mm |

|||

| Minimum molding size on both sides | 200mm | |||

| Minimum arc radius | 1.2mm | |||

| Fastest continuous bending speed | 0.5s/knife | |||

| Distance between upper and lower knives | 180mm (when the bending height is 320mm, the upper and lower tool distance is 325mm) | |||

| Bending angle | 0-360° | |||

| Maximum sheet thickness | 2mm aluminum plate/1.5mm carbon steel plate/1.2mm stainless steel plate | |||

| CNC system | Star300-LGx | |||

| operating system | Win7+OS | |||

| Number of axes (standard configuration) | 8 axis | AG:11 / AGP:12 axis | 13 axes | 13 axes |

| Number of axes (optional) | AGP: 14 axes | 14 axes | ||

| Equipment size | Length 3160mm

Width 1440mm Height 2870mm |

Length 3370mm / Length 4050mm

Width 1900mm / Width 1900mm Height 2740mm / Height 2780mm |

Length 4580mm

Width 2400mm Height 2950mm |

Length 5080mm

Width 2890mm Height 2950mm |

| equipment weight | 6000kg | 8500kg/9500kg | 13800kg | 18000kg |

※The AG series has a suction cup structure for loading, and the AGP has a downward pressure structure for loading.

※The equipment is updated from time to time. The pictures, functions, and specifications on this page are subject to change without prior notice. Please refer to the specifications on the latest quotation.

※Some functional accessories are optional.

Reference sample

|

|

|

|

|

|

|

|

|

|

|

|

Actual video

中文 (台灣)

中文 (台灣) Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.